Reliability proven through rigorious climate chamber testing

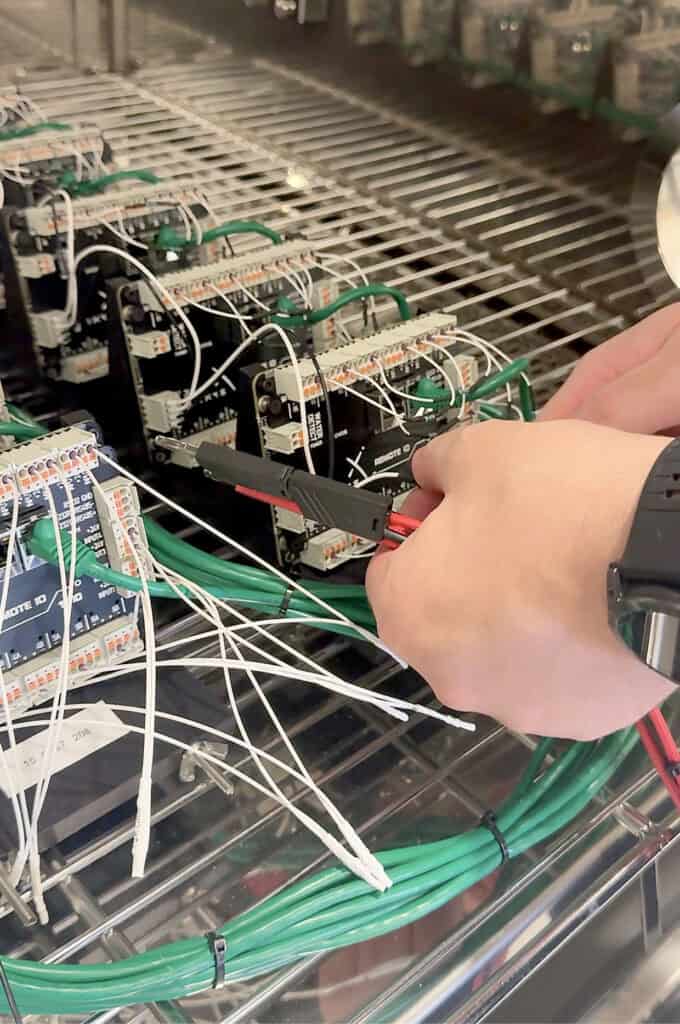

The latest round of electronic testing focused on verifying the Remote IO 1810 against the temperature specifications defined in its datasheet.

“We ramp the temperature up to a maximum of 70°C and hold it for 30 minutes before dropping it down to the minimum of -18°C,” explains Steffen Dugstad, System Technician.

Steffen Dugstad

System Technician

This thermal cycle is repeated ten times, followed by a burn-in test where the boards are held at 70°C for 48 hours to ensure 100% reliability. the full testing sequence lasts three days.

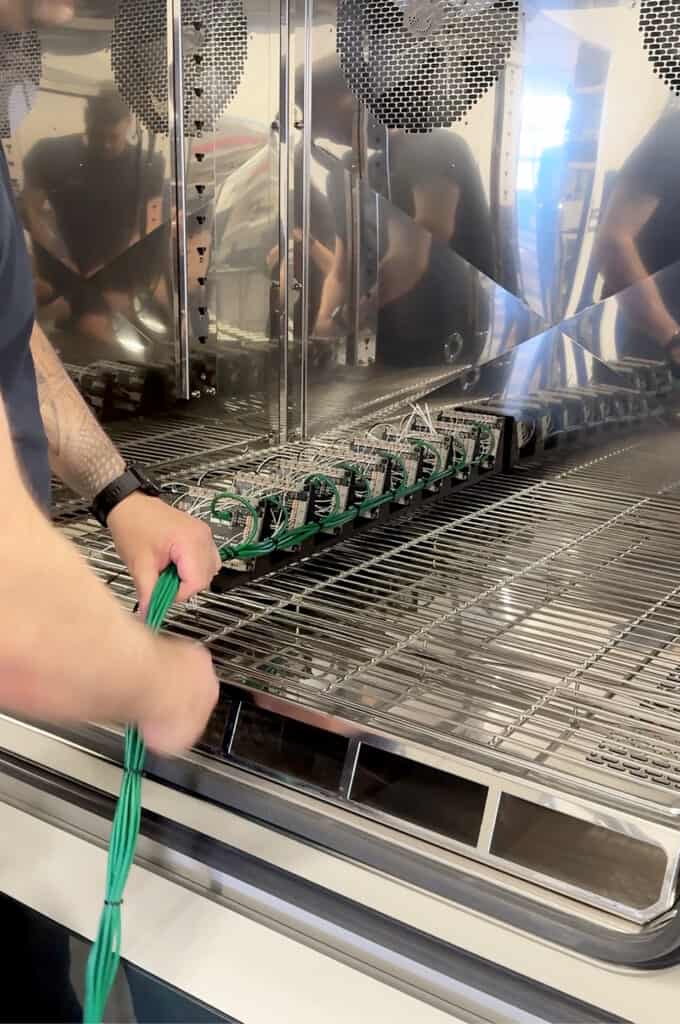

Climate chamber testing of 24 boards

A total of 24 Remote IO 1810 boards are carefully arranged in three rows before being placed inside the climate chamber for testing. Each board is connected to our VJU Studio software that logs every function during testing. “Our VJU Studio software continuously record all functions from each board, allowing us to detect even the smallest deviations from the expected performance,” adds Dugstad.

Ensuring reliability for demanding applications

By subjecting the Remote IO 1810 to extreme thermal cycling, burn-in testing, and continious communication monitoring, Ixys ensures that each board meets the highest standards for industrial reliability. These tests guarantee robust performance for valve control systems operationg in challenging environments.

Ixys pressure tolerant boards