Project scope

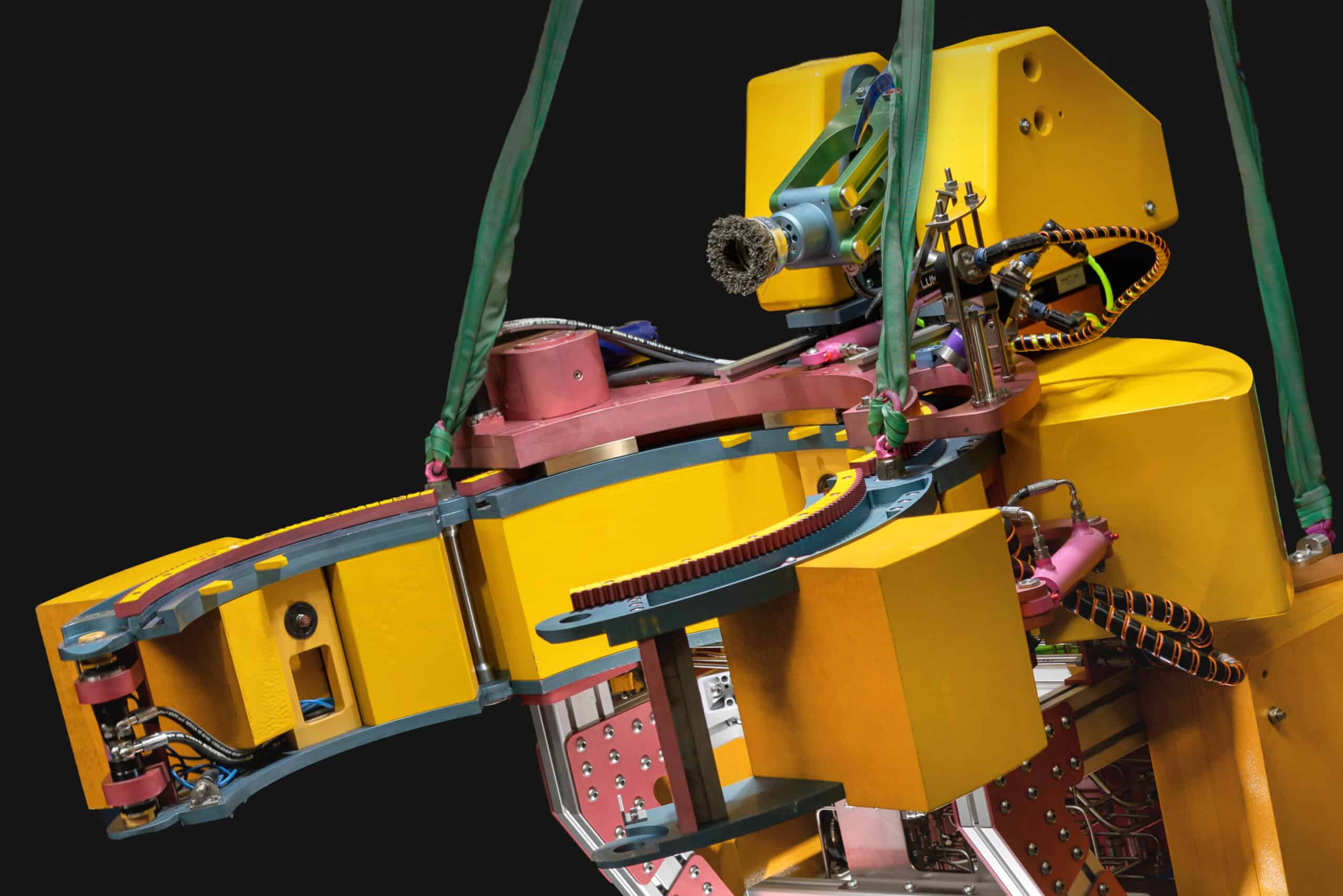

The project included the development and delivery of ROV-deployable tools for operations under an FPSO turret. This is a location with extremly limited accessibility and high operational complexity for ROV operations.

The primary objective was to enable coating removal, preparation for inspection, and re-coating/shielding without the use of divers. Transitioning to ROV-based operations significantly reduced risk, improved safety and enabled continuous operations.

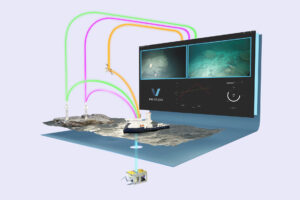

Why choose Ixys control system?

The project imposed high requirements for control and precision. IK Subsea selected Ixys control system to ensure:

• Robust subsea operation and integration with ROV/skid

• A clear and operator-friendly GUI for safe execution

• Support for automated operational sequences to reduce pilot workload and increase repeatability

• Integrated visual feedback via cameras in critical operational steps

• Fine-tuning and closed-loop automation for accurate coating removal around and on welds

• Short delivery time

• High degree of flexibility for special designs

• Inhouse engineering, design, production, testing and software leads to short processes

Ixys delivered the control system hardware, software (VJU/GUI), and camera solution that met these requirements and served as an operational platform for the offshore tools.

Phase 1: Assembly and testing

This phase included completion of design and test documentation, follow-up of fabrication, and assembly of the system, including tools, cameras, and sensors. The system function was verified through tank tests and inshore trials as part of qualification prior to the offshore campaign.

Phase 2: Installation and offshore operation

Phase 2 included mobilization, integration of the ROV and skid, and offshore operations. Typical offshore challenges related to operation, as-installed conditions, communication, power and camera configuration were handled continuously to ensure execution in accordance with scope.

“Ixys control system provided the robustness, precision, and operator support required for safe and repeatable subsea operations.”

Henrik Braune, Director of Engineering, IK Subsea

Control system in operation

The control system (VJU/GUI) was actively used as an operator platform, supporting both manual control and automated sequences, including bolt cutting operations. Communication and power-related integration challenges related to the interface between the ROV and skid were quickly resolved without affecting operational performance. The system allowed fully controlled stop and restart, as well as adjustment of essential operational parameters during execution.

Documented benefits

The control system contributed to several concrete benefits:

• Automated sequences with high repeatability and reduced operator workload

• Stop/restart functionality and auto-stop upon completed operations

• Clear and adjustable control parameters for flow and pressure

• Integrated camera view for visual verification in critical steps

• Standardized operation setup that can be reused and further developed in future campaigns

• Coating removal within +4/–0 mm tolerance on 300 mm de-coated area

• Precise centering along the weld centreline

“We achieved coating removal within close +4/–0 mm tolerance and perfect centring along the weld centreline.”

Olai Hagland, Senior Project Engineer, IK Subsea

Summary

The project was successfully executed offshore with a complete operational scope. The delivery represented a clear technological upgrade through automated operations, improved both safety and precision. At the same time, the project provided valuable operational experience and a solid foundation for future ROV-based operations in similarly demanding environments.