A need for better cable testing

When Vidar Kro, System Engineer, joined Ixys about a year ago, he quickly saw the potential for improvement in how cables were tested in the production line. At the time, the process involved manual measurements and report generation, a time consuming task both in production and in administration. Each unique test report required manual processing and routing to production.

“The need was twofold – we needed a system to improve the quality of cable testing and save time.”

Vidar Kro

System Engineer

Saving time and improving quality

The exact time saved per cable varies depending on the type being tested, but Vidar and Tomas estimate that Ixys now saves an average of 30 minutes per cable with the new cable test machine.

The new test reports are generated with data directy from the ERP system and is standardized, highly reliable, and uniquely detailed thanks to the advanced capabilities of the cable testing machine.

“The increased quality of the reports, with much more data available, is a benefit for our customers.”

Tomas Royal Choat

Embedded Engineer

Automating manual processes

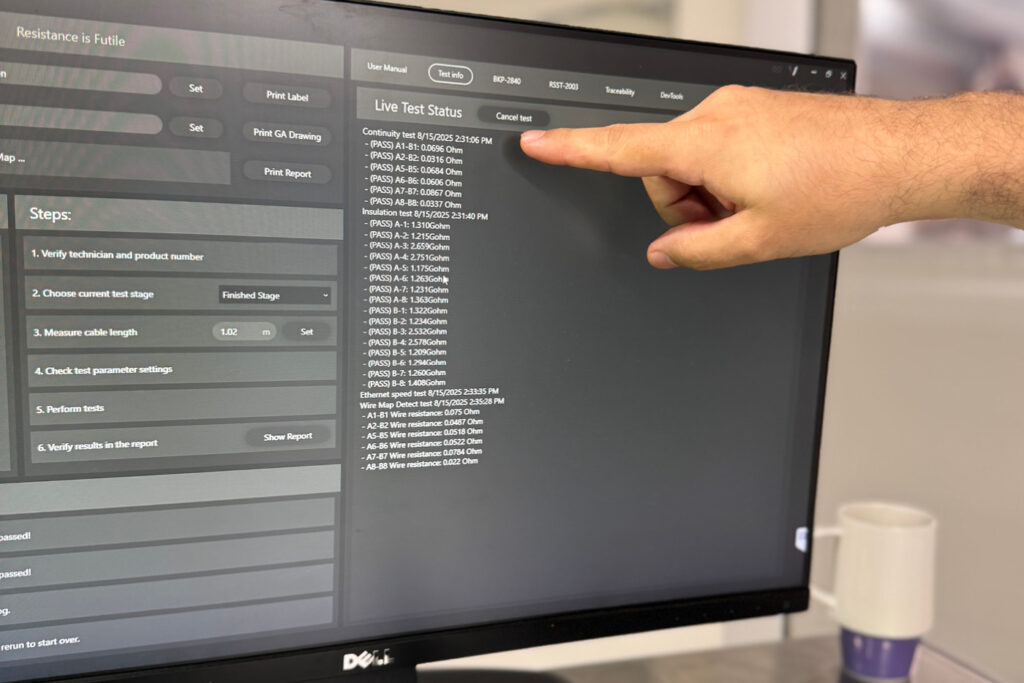

The new machine replicates the manual testing procedures previously performed, verifying connections and resistance within each cable. The system calculates expected resistance based on the cable type and length, ensuring accuracy and consistency.

Beyond connection verification, the machine tests each pin individually, checking for leakage to other pins or to ground. It also performs Ethernet speed testing and stores the serial numbers of all components used, providing a complete traceability record.

The implementation of this automated system has transformed cable production into a more enjoyable and efficient process for the Ixys team.

From concept to completion

The journey from idea to the finished product took approximately a year. Vidar has designed the overall system with following software infrastructure, while Tomas dedicated his expertise to write the software for the machine´s specific functionalities – a task that took between 3 and 4 weeks.

Satisfied customers with better test reports

Ixys customers have appreciated the quality of cable testing services. Now, they benefit from even more precise test reports containing a richer set of data and information than before.

Embracing innovation

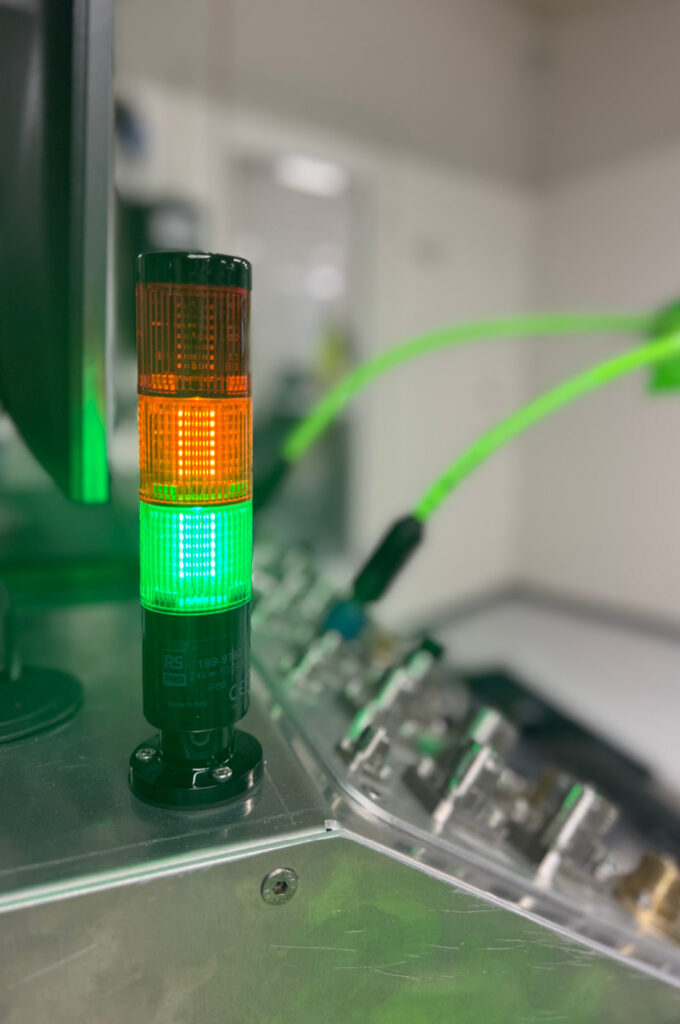

Vidar and Tomas proudly demonstrate the back of the cable testing machine, where a dazzling array of relays and lights create a captivating display. – I could sit here for hours just watching the lights, Tomas jokes.

With over 500 cables processed trough the new software and 300 cables scheduled for production and testing this fall, the new cable test machine is a welcome addition to Ixys production – and a clear example of how automation can enhance efficiency and quality in cable testing.