The integration between VJU Studio and MODFOX enables safe, efficient, and cost-effective control of subsea operations — even from shore.

What is MODFOX?

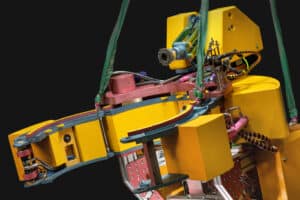

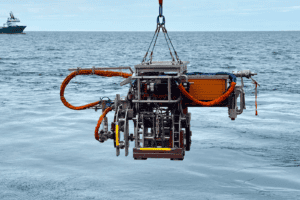

MODFOX is a modular subsea control system developed by FOX Subsea for installation and testing of subsea Xmas Trees at depths of up to 3,000 meters. Its modular architecture allows operators to quickly reconfigure and adapt the system to changing operational needs, reducing downtime and increasing flexibility.

Key benefits of MODFOX:

- Works at depths down to 3,000 m

- Modular and reconfigurable design

- Remotely operated from shore

- Low power consumption and environmental footprint

- Reduces offshore personnel and HSE risk

How VJU Studio powers the MODFOX system

VJU Studio simplifies the programming, visualization, and control of subsea systems.

At FOX Subsea, engineers were able to develop and operate the MODFOX control solution without hiring external software developers — significantly reducing both development time and costs.

“VJU Studio has allowed us to develop a safe and robust control system with remote operations capability, without the need of hiring specialized software delvopers. This has significantly reduced development time and operational costs for FOX Subsea.”

Bjørn Tore Lien

CCO at FOX Subsea

Delivered by Ixys:

- Subsea gateways for integration with tools and sensors

- Communication with Xmas Tree control systems

- Complete control software built in VJU Studio

Cutting operational time, cost and risk

MODFOX can be configured in multiple ways:

- SWOCS – umbilical-based systems

- RWOCS – ROV-based systems

- Wireless, battery-powered solutions

Its ability to stay permanently on the seabed and operate autonomously makes it ideal for deepwater fields, such as those off the coast of South America.

The result: faster operations, lower costs, and minimized HSE exposure.

Learn more about our control systems