Modern production line

We have a complete, modern production line at our facilities in Bryne. Here, we combine advanced machinery with strong technical expertise to deliver electronics, control systems and subsea components designed and built to withstand extreme conditions.

Streamlined PCB assembly line

Our automated and streamlined PCB assembly line, including advanced pick-and-place technology and selective soldering, gives us full control over both production flow and quality.

This setup ensures repeatability, precision, and efficiency at scale. Every board passes through a comprehensive PCB testing protocol.

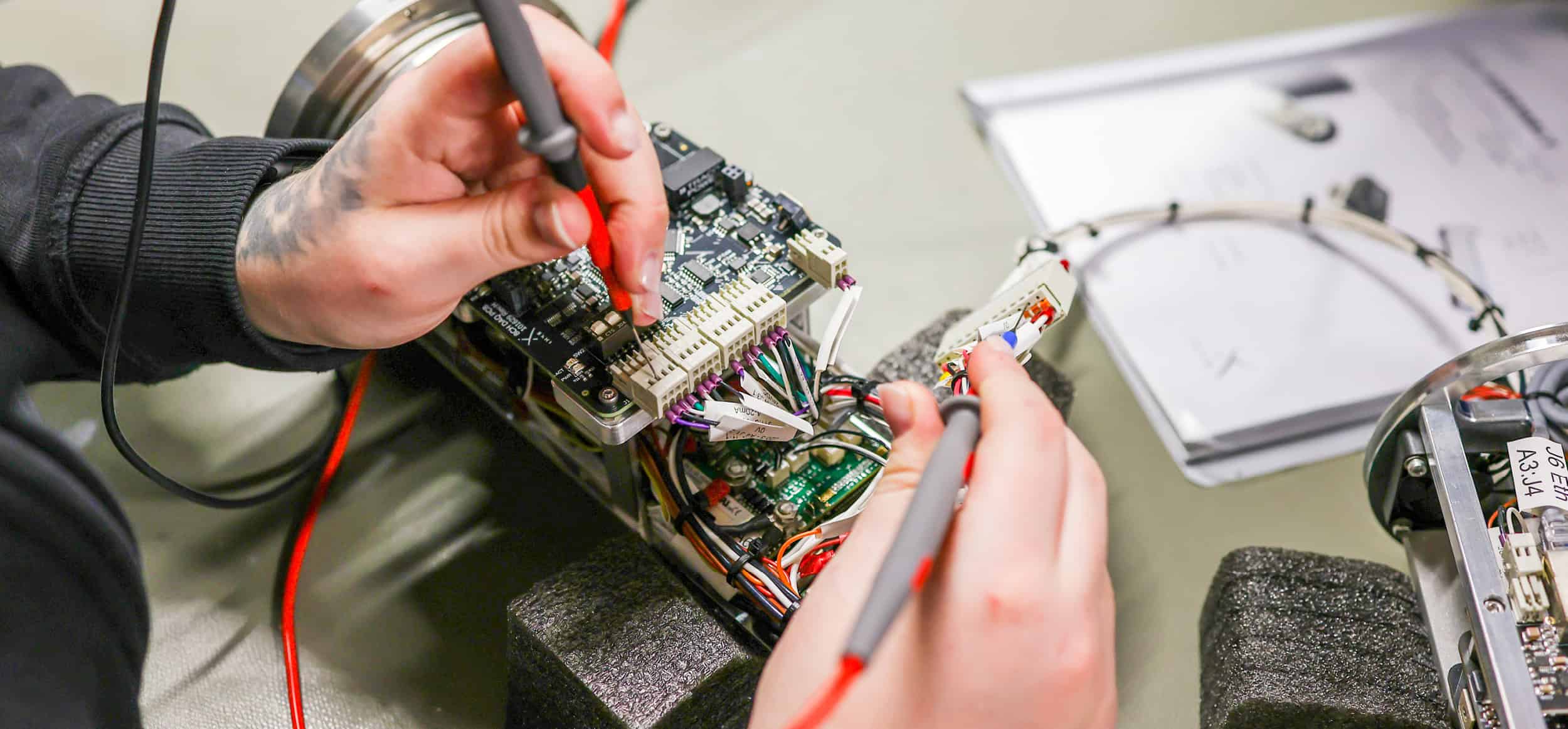

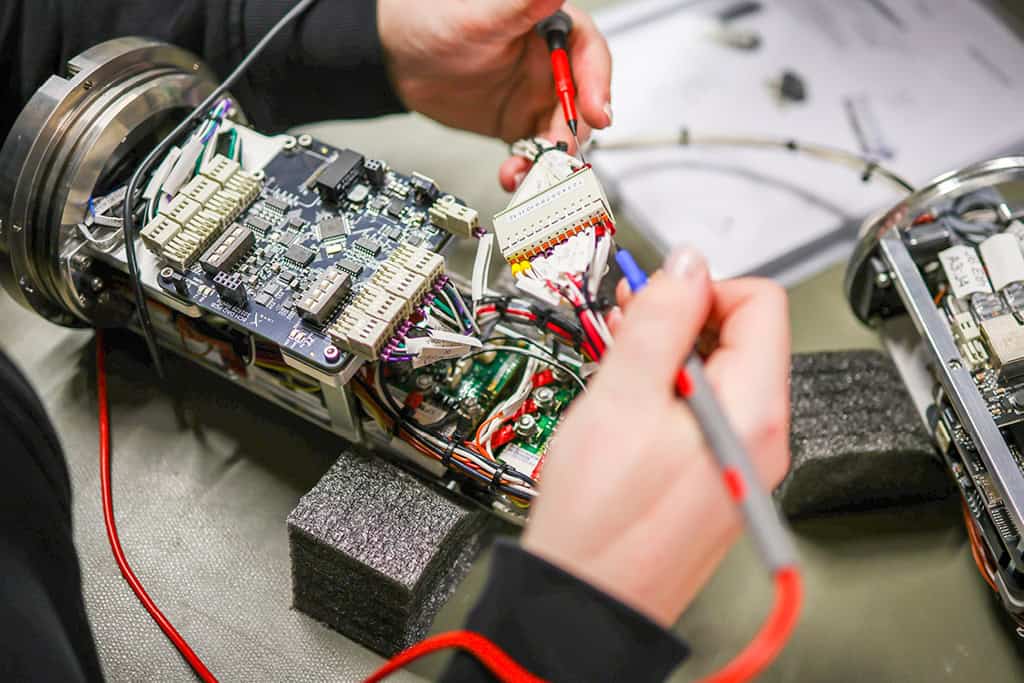

Electronic assembly

We specialize in electronic assembly, covering everything from board-level integration to final system configuration. Our experienced team builds each unit under strict quality control and full traceability, ensuring consistent and dependable performance in mission-critical applications.

All manual zones are fully ESD-protected, supported by procedures and personnel routines that safeguard our products throughout the entire process.

Cable assembly

Our in-house cable assembly and moulding capabilities enable us to deliver robust, custom cable solutions designed for harsh and demanding environments.

An automated mixing machine ensures efficient operations, consistent quality, and high precision throughout the production workflow.

For extreme conditions

We combine pressure-resistant housings with internal electronics and cabling tailored specifically for subsea use.

Each assembly is thoroughly tested to withstand extreme conditions, ensuring long-term stability, operational safety, and predictable performance in subsea applications.

Stocked standard components

We combine pressure-resistant housings with internal electronics and cabling tailored specifically for subsea use.

Each assembly is thoroughly tested to withstand extreme conditions, ensuring long-term stability, operational safety, and predictable performance in subsea applications.

Testing and documented quality

Every product is throughly tested in-house before delivery. All test data is logged and documented for full traceability and customer assurance.

In-house test capability

- Hyperbaric test chamber

- Climate chamber

- Cable machine tester

We also offer climate testing as a standalone service to qualify electronics or mechatronics components for harsh environments.

Contact our technical sales team.

RoHS compliance

Compliance is integrated into our material selection, sourcing, and production processes, with full documentation and traceability. We have implemented a quality assurance system according to EN ISO 9001:2008. Ixys AS assemble electronic circuit boards according to IPC-J-STD-001.

Contact our technical sales team for more information about our production, products or other services.

We are here to help you!

We give personalized advice and service. Our technical sales team is ready to help you find the best solutions for you.

Contact our sales team