The machine ensures more efficient operations, consistent quality, and higher precision throughout the production workflow. This investment is a strategic move to meet the growing demand for subsea cables.

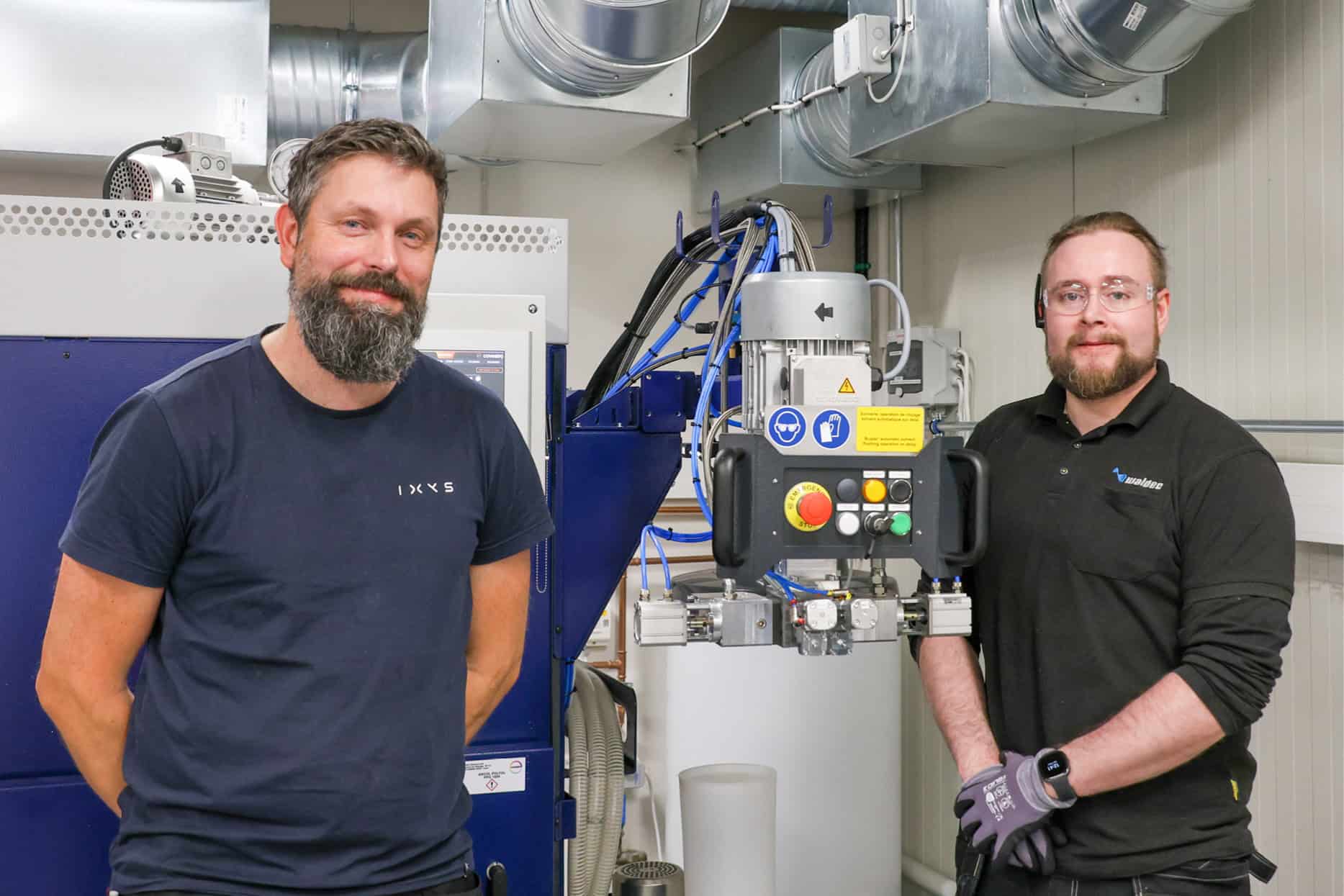

Installation and commissioning in collaboration with Waldec

Jan-Sebastian Hole, Maintenance Technician and Technical Sales at Waldec, is leading the installation work at Ixys. Over the course of three days, he supports the commissioning of the machine, demonstrates the raw materials, oversees the first production run, and trains the production staff. Waldec will also provide further support to ensure stable operation and optimal utilization.

“This machine gives Ixys a significant boost in both capacity and process control. When the molding compound is mixed automatically, they achieve more consistent quality and save time. Our goal is to ensure a safe start-up, solid training, and a system that works optimally from day one,” says Jan-Sebastian Hole, Maintenance Technician and Technical Sales at Waldec.

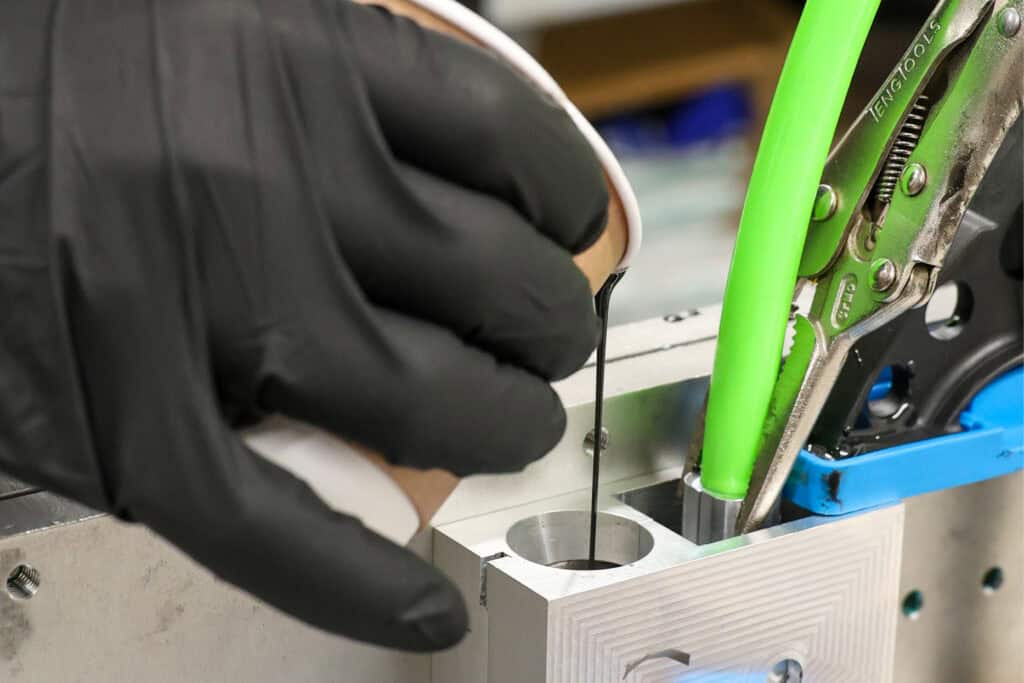

As part of the start-up, the tanks were emptied of neutral base used to keep the pumps lubricated during transport. The system and lines were then cleaned and prepared before new material could be filled and production initiated.

From manual mixing to automated precision

Previously, Ixys used pre-vacuumed-sealed 250-gram bags of molding compound. The new machine now enables continuous higher volumes production through a dedicated mixing chamber that adjusts the exact amount of molding compound delivered to each mold.

“The mixing chamber allows us to set precisely how much compound we need per mold. Manual mixing has been heavy work. We have had students helping in production before, and kneading the material correctly is physically demanding. We’ve even had a case of tendonitis, something we can now avoid thanks to automation,” says Jarl-Ove Haugen, Production Manager at Ixys.

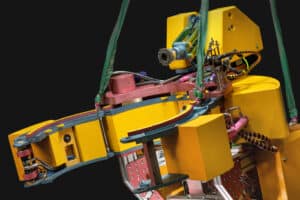

Improved material quality and stronger cables

Initial tests show that the automated process produces molding compound of very high quality — free of air bubbles, with high strenght and good elasticity. This is critical for cable longevity, especially in demanding subsea environments where pressure, vibration, and moisture can affect integrity.

The machine must be calibrated every morning, or before use, to ensure optimal performance. And the goal is for everyone in production to be trained to operate the machine independently.

Responding to increased market demand

Ixys has had a significant increase in cable sales over the past year. The new mixing machine is therefore a long-awaited addition, both to streamline production efficiency and improve overall quality.

Together with the new automated cable testing machine, this investment enables us to deliver cables of a very high standard to our customers.

Contact us

Need subsea cables? Contact our Technical Sales Team

Read more about our production upgrades

Read more about Waldec here.

Read more about the machine here.