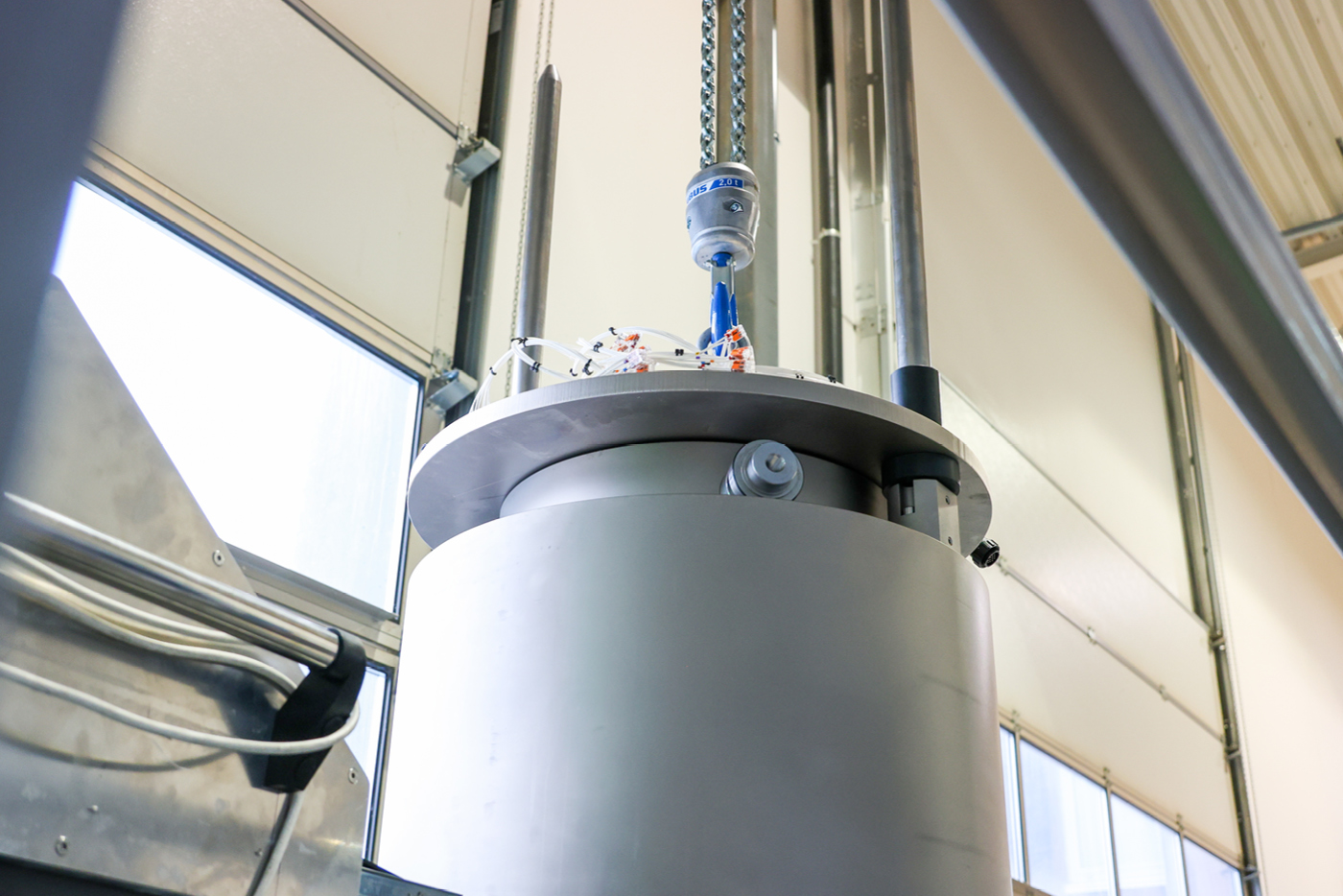

The chamber is capable of pressure testing down to 4,000 meters and has an internal volume of approximately 300 liters.

This marks a milestone in our ongoing work to strengthen in-house testing capabilities, increase our flexibility, and reduce dependence on external suppliers.

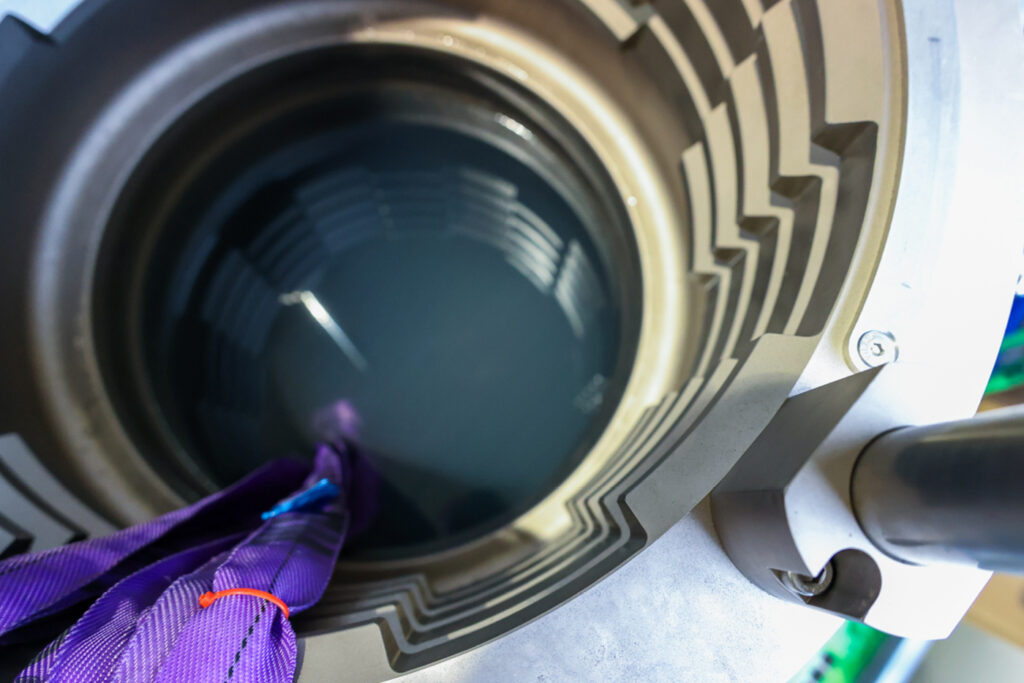

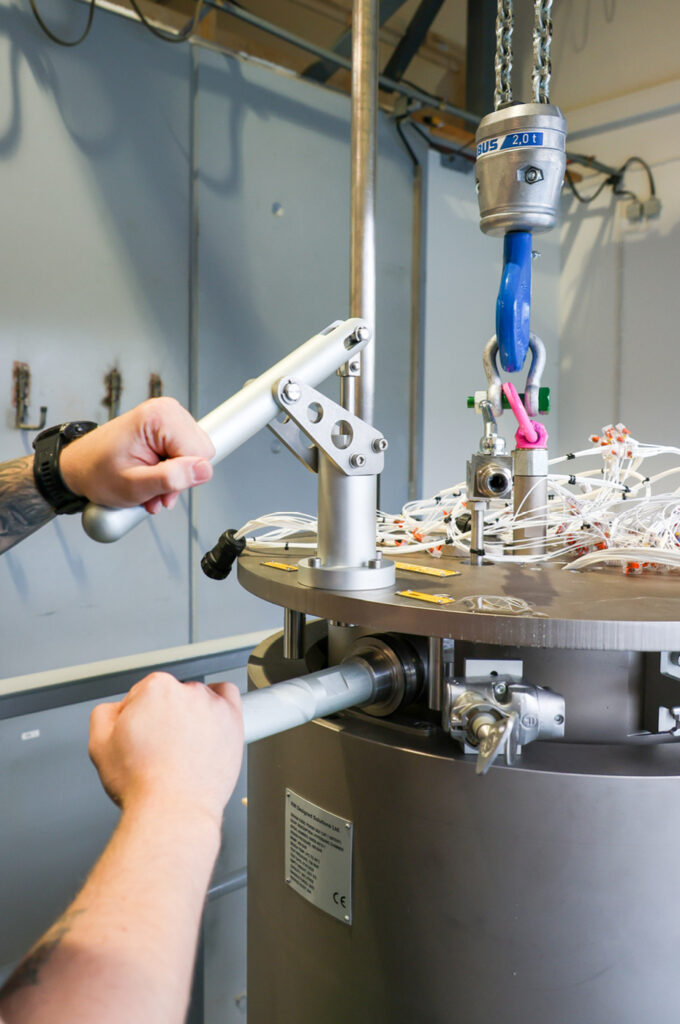

Innovative bolt-free design

This chamber stands out with its innovative bolt-free design and breech lock system, allowing the lid to be opened and closed effortlessly — literally with a finger. A newly installed crane handles the heavy lifting, raising the one-ton lid with precision. The main chamber itself weighs about 2.5 tons.

Increased efficiency with custom mini canisters

The chamber will primarily be used for pressure testing of subsea canisters and for extended testing of cables. However, it is also designed to accommodate a wide range of other subsea products. In addition, Ixys engineers have developed custom mini canisters that can be mounted in the lid, enabling multiple cables to be tested simultaneously and thereby improving overall efficiency.

“This new chamber can handle up to five cables at once, which can save us four to five hours of work per test,” says Steffen Dugstad, System Technician at Ixys.

Reliable and cost-efficient testing for subsea products

With this investment, Ixys further strengthens its capability to deliver safe, reliable, and cost-efficient pressure testing for subsea products and equipment. Moreover, the new hyperbaric chamber replicates extreme deep-ocean pressures and temperatures, allowing precise simulation and control of the harsh conditions subsea technology encounters in everyday operations.

Advanced performance and specifications

KW Designed Solutions hyperbaric chambers feature internal diameters ranging from 20 mm to 2,500 mm. Built for extreme conditions, they are engineered to withstand pressures of up to 2,750 bar (40,000 psi) and temperatures from –40°C to +300°C.

Furthermore, these advanced systems are used worldwide for Factory Acceptance Testing (FAT) and New Product Development (NPD). As a result, they help ensure exceptional performance, reliability, and safety even under the most demanding conditions.

Read more about Ixys’ in-house testing and production upgrades

Read more about KW Designed Solutions here.

Read more about Hyperbaric chambers here.